Advanced circuit breakers are crucial in electrified aircraft with megawatt-levels of electricity onboard. Researchers at NASA are developing circuit-breaking devices that are lightweight with rapid response times to help protect aircraft systems from potential electrical safety issues.

Overview

Electrifying aircraft safely and reliably requires advanced electrical systems that are lightweight, energy efficient, and capable of managing significant amounts of electrical power and heat during flight.

When operating at high altitudes with increased voltages, electric aircraft powertrains must have safety systems that are able to quickly respond in the event of an electrical failure, as well as transfer heat efficiently throughout the vehicle to maximize performance and reduce fuel consumption.

Managing Electrical Power

Advanced electrified aircraft propulsion (EAP) technologies could improve safety of aircraft electrical systems by mitigating the potential dangers of high-voltage electricity, such as electrical arcing caused when currents flow through the air between conductors.

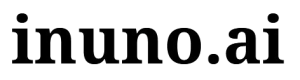

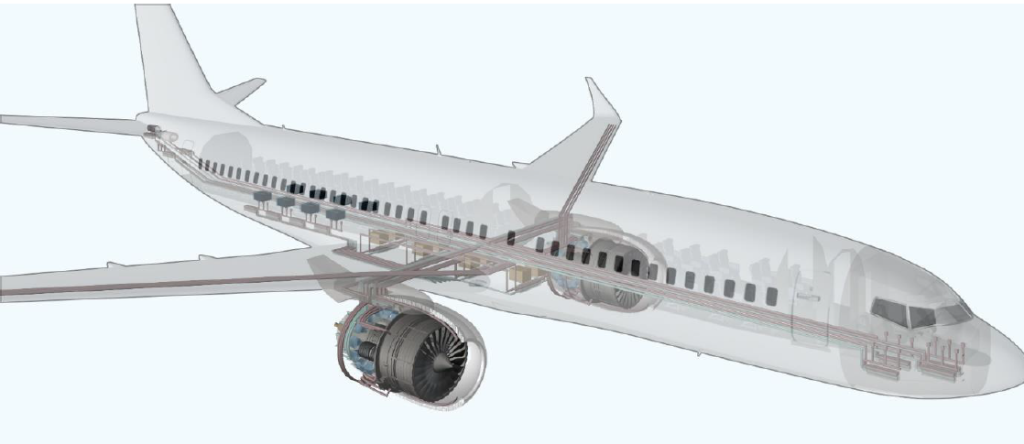

A typical house has circuit breakers, appliance fuses, and ground-fault circuit interrupter (GFCI) outlets all designed to detect an overload or electric short and “trip,” or shut off. This stops the flow of electricity to or from a certain area until the problem can be corrected. On an electrified airplane, circuit breakers are distributed throughout the plane as part of a fault management system that detects any electrical issues and takes action to protect the motors, batteries, and other electrical parts.

The challenge is developing circuit-breaking devices that are strong enough to stop megawatts of energy, able to respond in 100 microseconds or less, and 10 times lighter than anything built yet.

EAP research focuses on developing fault management systems with advanced circuit breakers that will protect aircraft from safety hazards by stopping the flow of electricity in an area where there is an electrical issue.

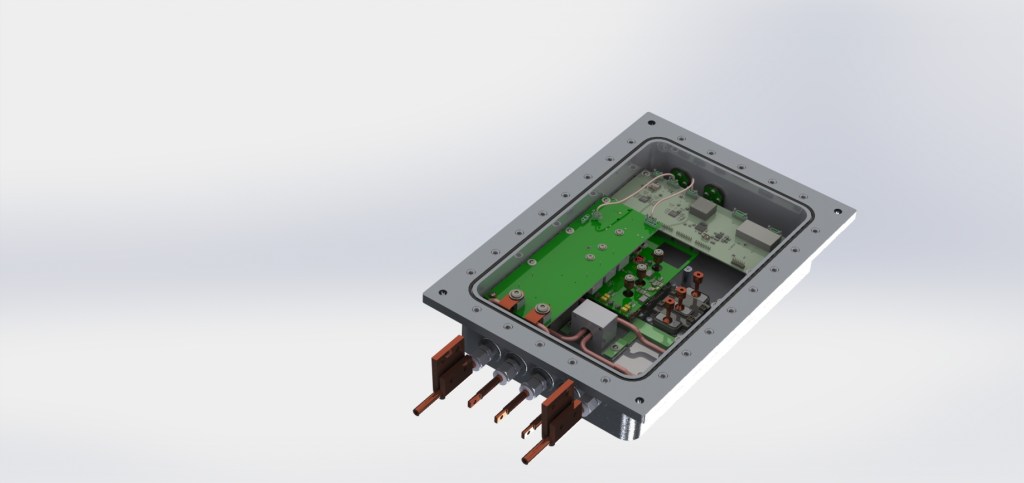

With most electric aircraft running on high-voltage direct current (DC) power, circuit-breaking devices designed must be lightweight, quick-responding, and strong enough to manage megawatts (MW) of electricity. EAP research is advancing new circuit-breaking technology for electrified aircraft with DC solid-state circuit breakers equipped with high-voltage semiconductors.

Distributed across the aircraft, solid-state circuit breakers have a significantly quicker response time and are able to interrupt power flow in a few microseconds compared to traditional mechanical circuit breakers.

Circuit Breaker Technology

Under the Advanced Air Transport Technology (AATT) project, NASA is developing MW-scale circuit breakers to achieve effective fault management. To manage MW-class power levels with 99.5% efficiency, these advanced circuit-breaking devices will operate at a targeted voltage of 1 kilowatt (kW), a current of 1000 ampere (A), and a specific power – or power-to-weight ratio of 100 kW/kg.

The circuit breakers will also have a 100 ms response time, which will play a key role in controlling the flow of dangerous energy. Since electrified aircraft will operate at altitudes of approximately 35,000 feet where atmospheric pressure is low, there is an increased risk of electrical arcing. These circuit breakers are designed to operate in this reduced atmosphere environment and protect against potential hazards.

| Metric | Minimum | Expected | Stretch |

|---|---|---|---|

| Specific Power (kW/kg) | 50 | 100 | 200 |

| Voltage (kV) | 0.8 | 1 | >2 |

| Current (A) | 800 | 1000 | >1000 |

| Response (us) | 250 | 100 | 10 |

| Efficiency (%) | 99.3 | 99.5 | 99.97 |

| Altitude (ft) | 25,000 | 35,000 | 51,000 |

Controlling Excess Heat

Electric aircraft safety systems also have the challenge of managing large amounts of heat that must be transferred efficiently throughout the vehicle during flight. Low-grade waste heat released from solid-state circuit breakers, inverters, converters, and other electric aircraft components is often low in temperature and difficult to use and transfer throughout the vehicle, therefore reducing fuel efficiency and performance.

New thermal energy conversion technologies use acoustic waves to transform low-grade waste heat to higher temperatures that can be used more efficiently throughout the aircraft.

Meeting Future Electrified Aircraft Demands

Managing megawatts of power and increased low-grade waste heat onboard, advanced circuit-breaking technology and improved thermal management systems are crucial in protecting personnel, electronics, and airframe structure.

EAP research is advancing this technology with faster response times, increased efficiency, and the altitude capability to enable electrified aircraft propulsion on the megawatt scale. These innovations in fault and thermal management systems will help address key challenges in electrifying flight and demonstrate innovative solutions to keeping aircraft safe and improving fuel efficiency for more sustainable air travel.

Fault Management Fact Sheet

Resources

Publications

Explore and download a collection of publications highlighting circuit breaker development at NASA.

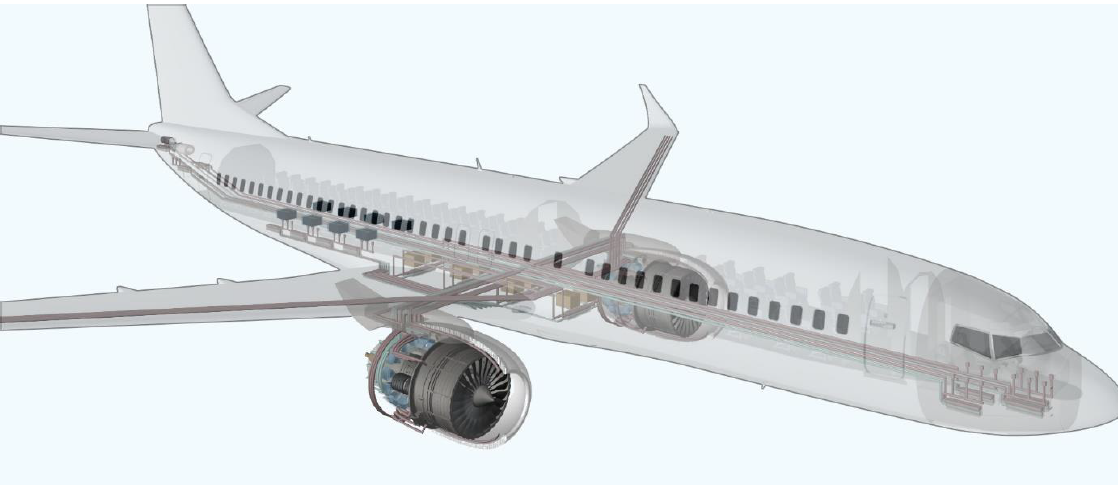

Aircraft Concepts

Learn more about NASA’s conceptual aircraft design studies for future electrified aircraft.

EAP Labs and Testbeds

Learn about NASA’s labs and testbeds enabling advanced electrified aircraft propulsion research.

Technology

Discover the innovative systems and technologies that enable safe and efficient electrified propulsion.