Efforts to increase U.S. Army warfighter capability and repair efficiency in theater were strengthened with the recent inception of an aviation engine repair shop.

Over a year ago, an aviation logistics officer with the 1st Theater Sustainment Command, Chief Warrant Officer 3 Codi Walker, brought forth a plan for an expeditionary engine shop in the U.S. Central Command area of responsibility.

This plan was pitched to the 1st TSC commander, Maj. Gen. Eric Shirley, by the Aviation Field Maintenance Directorate at Redstone Arsenal, Alabama. The plan was approved and would proceed as a three-phase project.

Helming the project is the 1100th Theater Aviation Support Maintenance Group, a National Guard unit from Edgewood, Maryland, and the 1st TSC forward aviation pillar in theater.

The 1100th worked directly with Department of the Army civilians in Logistics Readiness Center-Alpha, Ainsley Vickers, LRC-A CENTCOM chief, and Valkeith Williams, logistics management specialist. Along with the 1st TSC, the LRC-A is based at Fort Knox, Kentucky.

Col. Jeremy Chiglo, commander, 1100th TASMG, moved from Alabama to Maryland to serve as the Maryland State Aviation Officer, shortly before the unit deployed overseas. He brought with him three Soldiers from Alabama, who also deployed.

“The National Guard has five TASMGs that support both the U.S. Aviation Missile Command and the 1st TSC. The TASMGs rotate through theater every 9 months and all TASMGs share this responsibility,” said Chiglo.

In addition to the Maryland TASMG, there are four throughout the continental U.S.; the 1106th from California, the 1107th from Missouri, 1108th from Mississippi, and the 1109th from Connecticut.

“We’ve been here about four months,” continued Chiglo. “When we first arrived, the engine shop had been conceptualized, there was a plan passed down to us from our predecessors, the 1108th. LRC-A and Chief Walker had secured the budget, as well as the containers.”

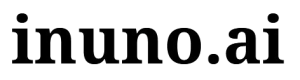

The containers are military-owned expandable containers similar to a shipping container, were already present in theater and roughly placed before the 1100th TASMG took command. These containers were acquired and sent by AFMD and came equipped with basic tools for engine repair.

Chiglo shared that, within the force structure of the TASMG, the Soldiers focus on routine and unscheduled aviation maintenance, and the bulk of the engine repair is done by contractors with Amentum, an aviation maintenance company, who are overseen by the DA civilians in LRC-A.

The 1100th were tasked to stand up the shop in four or five months, and they were able to complete it in half the time. “My biggest worry were the technical experts,” said Chiglo. “Once LRC-A secured the Amentum contractors for us, we were able to get the containers lined up and get power to the shop. It took us about a month just to procure the necessary parts.”

The first phase of the project was finalized with the engine shop’s inaugural ribbon-cutting, October 31, 2024. The shop is currently housed in two adjacent SPAMS and services two helicopter engines, the T-701, which seamlessly fits both the AH-64 Apache and UH-60 Black Hawk, and a T-55, for the CH-47 Chinook.

The next two phases include moving to a larger hard structure and acquiring a Modernized Flexible Engine Diagnostic System, a large machine capable of fully testing and verifying engines.

Chiglo explained that although theoretically an engine could be tested and verified by hanging it back on the aircraft, the risk of compromising the safety and readiness of warfighters is too high.

“What we’re doing now is bridging the gap. The contractors will repair the engine, then, as a temporary measure, it will be routed to the Theater Aviation Sustainment Management – OCONUS (Outside Continental U.S.), for a final test run of the engine.”

An MFEDS is not always required to repair an engine back to full functionality, but Chiglo clarified that it could still save valuable time up front by diagnosing the problems. Without an MFEDS, technicians must dismantle an engine for diagnosis before they can begin the repairs, a process that is both timely and costly.

Since opening, the engine shop has already repaired a T-55, which did not require an MFEDS, and has returned it to its aviation unit. The shop is currently awaiting the final part for the cold section of a T-701, before the engine will be sent for testing on the TASM-O’s MFEDS.

“Our goal is to have everything we need here in theater – to fix engines, test them, and return them, while also being fiscally responsible,” concluded Chiglo.

The engine shop ultimately aims to expedite the repair and return of fully functional engines to the warfighter and aviation units, while saving the Department of Defense funds by reducing the expenditure of repair, maintenance, and new equipment.

As a new cornerstone of the Army’s aviation maintenance efforts, the shop plays a crucial role in ensuring readiness of Army aviation capabilities in theater.

| Date Taken: | 03.03.2025 |

| Date Posted: | 03.03.2025 15:49 |

| Story ID: | 491917 |

| Location: | (UNDISCLOSED LOCATION) |

| Web Views: | 1 |

| Downloads: | 0 |

PUBLIC DOMAIN

This work, 1st TSC Revolutionizes Aviation Engine Repair in CENTCOM, by Vanessa Schell, identified by DVIDS, must comply with the restrictions shown on https://www.dvidshub.net/about/copyright.